Oil sands and Conventional Energy Projects

Exploration

and

production

of

energy

accounts

for

6.2%

of

Canada's

GDP.

This

industry

faces

significant

transportation

challenges

given

where

the

reserves

occur.

Below

is

a

summary

of

the

importance the energy industry has to Canada as a primary economic driver:

Capital Spending:

Conventional

$26.8 billion

Oil Sands

$6.2 billion

Total

$33.0 billion

Wells Drilled

Oil:

4,526

Natural Gas:

15,126

Total (including Dry & Service):

24,874

Reserves at

2004 Year End:

Conventional Oil:

4,354 million barrels

Surface Mining

(Integrated Synthetic):

5,294 million barrels

In-situ bitumen:

2,082 million barrels

Natural Gas:

56.5 trillion cubic feet

Production:

Conventional Oil:

1,410,000 barrels per day

Surface Mining

Integrated Synthetic:

465,000 barrels per day

In-situ bitumen:

532,000 barrels per day

Pentanes plus/condensate:

163,000 barrels per day

Crude oil & equivalent:

2,570,000 bar rels per day

Natural Gas:

17.0 billion cubic feet per day

Governments:

Royalties, Bonuses,

Fees & Income Taxes

$18.0 billion

Employment:

Direct and Indirect

365,000

Total Employment Impact

500,000

Exports:

Crude Oil:

1,611,000 barrels per day

Natural Gas:

9.7 billion cubic feet per day

The three major activities within this sector are oil sands, conventional production and

pipelines. Each of these activities gives rise to major transportation challenges. Sometimes the

challenge relates to the remoteness of the location or its inaccessibility due to ground condition.

This is the case with the northern boreal areas where it is only possible to move drilling

equipment during the winter season when the muskeg is frozen. The oil sands face a different

challenge. Large invisible loads must be moved to the constructions sites at great expense and

disruption given that there is only one road and one rail line from the south to Fort McMurray.

Oil sands Development

The development of the Alberta Oilsands is a mega project on a grand scale. The Alberta

Government estimates that new and sustaining capital requirements to produce this resource

may reach $93.5 billion over its expected 30-year life. The Canadian

Association of Petroleum Producers (CAPP) estimates that the Oilsands will account for up

15% of the world's oil crude oil reserves.

Oil sands production has surpassed one million barrels per day and with 175 billion barrels of

reserves in the ground it is one of the few basins in the world with growing production.

Companies expect to produce 2.9 million barrels per day of bitumen and synthetic light crude

oil by 2015. To appreciate the immense scope of the second largest petroleum deposits in the

world after Saudi Arabia, consider that at current production rates it would take over 400 years

just to deplete the reserves at existing oil sands operations. Overall, Canada has 15 per cent of

the world's crude oil reserves, produces 2.5 million barrels per day, and is the largest and most

reliable foreign supplier to the United States.

CAPP 2004

A report issued by the Alberta Economic Development in the spring 2005 provides a very

comprehensive overview of the status of the individual projects.

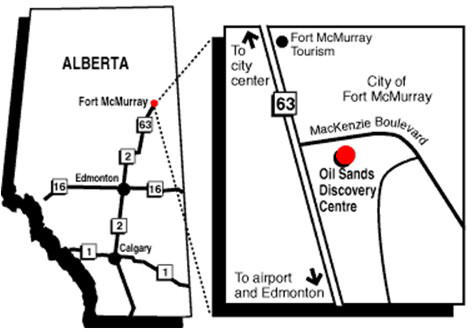

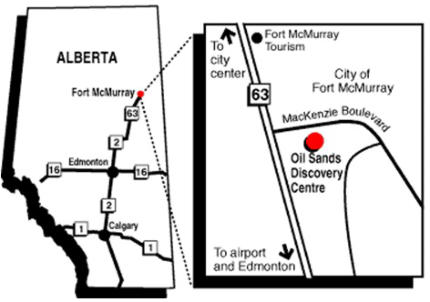

The Oilsands are located in Fort McMurray, Alberta. Most of the major equipment is imported

and much of the construction is being done off site and transported to the projects in modules

from Edmonton. Highway 63 is a two-lane highway and provides the only road to Fort

McMurray. This highway is often congested because large loads must be moved at slow speeds

along its 457 kilometre length.

Many of the world's largest energy companies have projects that are operational, under

construction or planned. Included are companies such as Imperial Oil (Exxon), Shell, Petro

Canada, EnCana, Nexen, Suncor, Syncrude, etc.

In addition to the movement of large industrial equipment, there is a need to move other

types of construction and extraction related material. The objective in the mining operation is

to move as much material as possible. The limit to the size of the mine trucks is the largest

tire that can be transport to the site. Most of the other truck parts can be disassembled into

pieces that to be moved by road or rail. However, a tire, by definition is an indivisible load. If

the mines want to build larger trucks they need to transport the tires to the mine. At Suncor,

there are 30 trucks, each has 6 tires and a tire lasts about 11 months. They need about 180

tires per year. An individual tire weights about 8,000 lbs. They spend about $8 million per year

on tires alone. If hybrids could transport larger tires, the potential benefits to the mines would

be very significant.

On a daily basis, over 300 hundred bus loads of workers are transported from the city of Fort

McMurray to the project sites. This is a time consuming and costly exercise given the limited

road capacity and bridges in the area. The furthest site is 125 km, one-way, from Edmonton.

An option for moving passengers by hybrid air vehicle could be well received.

In summary, hybrid air vehicle could be used for at least the following missions in the

energy industry:

Movement of larger industrial equipment from ports or inland manufacturing facilities

to the project construction sites.

Movement of large indivisible loads that have clearance that exceed the road and/or rail

allowances.

Movement of people and supplies from the rail head in Fort McMurray to site.

The Oilsands projects are of a scale and duration (30+ years of forecasted

construction) that the transportations requirements stemming from this industrial

activity alone could justify the development of a fleet of hybrid air vehicle of varying

capacities and mission requirements. This may be a killer application this industry has

sought for so long.

Conventional Exploration and Production

Energy exploration and production is distributed over a broad geographic area. This

necessitates transporting significant volumes of oilfield related equipment, supplies and

construction materials and equipment. In the southern areas, roads and truck transportation

provide adequate options for moving most products. However in the north, the two most

significant issues are the lack of roads in some areas and inaccessibility of these roads during

a significant portion of the year due to the adequacy of the roads and soft conditions during

break-up that necessitate road bans. These factors contribute to seasonality and peaking

issues that result in increased direct costs or opportunity costs.

A case in point, is seasonally drilling activity. The recent surge in energy prices has put further

pressures on the energy industry to explore and produce new wells. As the oil extraction

industry drains the easy to access sedimentary basins, new capacity is being sought in the

more logistically challenging Arctic climate zones. In much of northern Canada and Alaska, local

ground conditions severely inhibit oil and gas drilling activity. Oil drilling in areas with muskeg

or marshy conditions requires the ground to be frozen before heavy drilling rig equipment can

be transported. During the remainder of the year, impassable mud and environmental

restrictions prohibit surface transport to these sites.

Copyright © 2023

Millennium Airship Inc/SkyFreighter Canada Ltd

Oil sands and Conventional Energy Projects

Exploration

and

production

of

energy

accounts

for

6.2%

of

Canada's

GDP.

This

industry

faces

significant

transportation

challenges

given

where

the

reserves

occur.

Below

is

a

summary

of

the

importance

the

energy

industry

has

to

Canada

as

a

primary economic driver:

Capital Spending:

Conventional

$26.8 billion

Oil Sands

$6.2 billion

Total

$33.0 billion

Wells Drilled

Oil:

4,526

Natural Gas:

15,126

Total (including Dry & Service):

24,874

Reserves at

2004 Year End:

Conventional Oil:

4,354 million barrels

Surface Mining

(Integrated Synthetic):

5,294 million barrels

In-situ bitumen:

2,082 million barrels

Natural Gas:

56.5 trillion cubic feet

Production:

Conventional Oil:

1,410,000

barrels

per

day

Surface Mining

Integrated Synthetic:

465,000 barrels per day

In-situ bitumen:

532,000 barrels per day

Pentanes plus/condensate:

163,000 barrels per day

Crude oil & equivalent:

2,570,000

bar

rels

per

day

Natural Gas:

17.0 billion

cubic

feet

per day

Governments:

Royalties, Bonuses,

Fees & Income Taxes

$18.0 billion

Employment:

Direct and Indirect

365,000

Total Employment Impact

500,000

Exports:

Crude Oil:

1,611,000

barrels

per

day

Natural Gas:

9.7 billion

cubic

feet

per day

The three major activities within this sector are oil sands,

conventional production and pipelines. Each of these activities

gives rise to major transportation challenges. Sometimes the

challenge relates to the remoteness of the location or its

inaccessibility due to ground condition. This is the case with the

northern boreal areas where it is only possible to move drilling

equipment during the winter season when the muskeg is frozen.

The oil sands face a different challenge. Large invisible loads must

be moved to the constructions sites at great expense and

disruption given that there is only one road and one rail line from

the south to Fort McMurray.

Oil sands Development

The development of the Alberta Oilsands is a mega project on

a grand scale. The Alberta Government estimates that new and

sustaining capital requirements to produce this resource may

reach $93.5 billion over its expected 30-year life. The Canadian

Association of Petroleum Producers (CAPP) estimates that the

Oilsands will account for up 15% of the world's oil crude oil

reserves.

Oil sands production has surpassed one million barrels per day

and with 175 billion barrels of reserves in the ground it is one of

the few basins in the world with growing production. Companies

expect to produce 2.9 million barrels per day of bitumen and

synthetic light crude oil by 2015. To appreciate the immense

scope of the second largest petroleum deposits in the world after

Saudi Arabia, consider that at current production rates it would

take over 400 years just to deplete the reserves at existing oil

sands operations. Overall, Canada has 15 per cent of the world's

crude oil reserves, produces 2.5 million barrels per day, and is

the largest and most reliable foreign supplier to the United

States.

CAPP 2004

A report issued by the Alberta Economic Development in the

spring 2005 provides a very comprehensive overview of the

status of the individual projects.

The Oilsands are located in Fort McMurray, Alberta. Most of the

major equipment is imported and much of the construction is

being done off site and transported to the projects in modules

from Edmonton. Highway 63 is a two-lane highway and provides

the only road to Fort McMurray. This highway is often congested

because large loads must be moved at slow speeds along its 457

kilometre length.

Many of the world's largest energy companies have projects

that are operational, under construction or planned. Included

are companies such as Imperial Oil (Exxon), Shell, Petro

Canada, EnCana, Nexen, Suncor, Syncrude, etc.

In addition to the movement of large industrial equipment,

there is a need to move other types of construction and

extraction related material. The objective in the mining

operation is to move as much material as possible. The limit to

the size of the mine trucks is the largest tire that can be

transport to the site. Most of the other truck parts can be

disassembled into pieces that to be moved by road or rail.

However, a tire, by definition is an indivisible load. If the mines

want to build larger trucks they need to transport the tires to

the mine. At Suncor, there are 30 trucks, each has 6 tires and a

tire lasts about 11 months. They need about 180 tires per year.

An individual tire weights about 8,000 lbs. They spend about $8

million per year on tires alone. If hybrids could transport larger

tires, the potential benefits to the mines would be very

significant.

On a daily basis, over 300 hundred bus loads of workers are

transported from the city of Fort McMurray to the project sites.

This is a time consuming and costly exercise given the limited

road capacity and bridges in the area. The furthest site is 125

km, one-way, from Edmonton. An option for moving passengers

by hybrid air vehicle could be well received.

In summary, hybrid air vehicle could be used for at least the

following missions in the energy industry:

Movement of larger industrial equipment from ports or

inland manufacturing facilities to the project construction

sites.

Movement of large indivisible loads that have clearance that

exceed the road and/or rail allowances.

Movement of people and supplies from the rail head in

Fort McMurray to site.

The Oilsands projects are of a scale and duration (30+

years of forecasted construction) that the transportations

requirements stemming from this industrial activity alone

could justify the development of a fleet of hybrid air vehicle

of varying capacities and mission requirements. This may be

a killer application this industry has sought for so long.

Conventional Exploration and Production

Energy exploration and production is distributed over a broad

geographic area. This necessitates transporting significant

volumes of oilfield related equipment, supplies and

construction materials and equipment. In the southern areas,

roads and truck transportation provide adequate options for

moving most products. However in the north, the two most

significant issues are the lack of roads in some areas and

inaccessibility of these roads during a significant portion of the

year due to the adequacy of the roads and soft conditions

during break-up that necessitate road bans. These factors

contribute to seasonality and peaking issues that result in

increased direct costs or opportunity costs.

A case in point, is seasonally drilling activity. The recent surge

in energy prices has put further pressures on the energy

industry to explore and produce new wells. As the oil extraction

industry drains the easy to access sedimentary basins, new

capacity is being sought in the more logistically challenging

Arctic climate zones. In much of northern Canada and Alaska,

local ground conditions severely inhibit oil and gas drilling

activity. Oil drilling in areas with muskeg or marshy conditions

requires the ground to be frozen before heavy drilling rig

equipment can be transported. During the remainder of the

year, impassable mud and environmental restrictions prohibit

surface transport to these sites.

Copyright © 2023

Millennium Airship Inc/SkyFreighter Canada Ltd